Questions frequently arise around the difference between Vinyl and Hybrid flooring types. Often the terms are used interchangeably, but the reality is while they have elements in common, they are 2 very different product categories. Let’s take a look at these products and see how hybrid flooring vs vinyl planks differ and where one should be used over the other.

The Differences & Similarities Between Hybrid vs Vinyl Flooring

Vinyl Plank flooring is individual planks that are laid on the subfloor using either a Pressure Sensitive Adhesive or a full Hard-Set Adhesive. They are soft and quite flexible with little rigidity. Hybrid planks on the other hand have a locking system and lock together in the same way as Laminate and Engineered Timber Flooring. The product is quite rigid compared to Vinyl Planks.

1. Wear Layer

Both Vinyl Plank and Hybrid Flooring use a polyurethane PVC Wear Layer. This is the same wear layer on both products. This wear layer has good scratch and stain-resistant properties. It has been used for many years as a commercial wear layer and is tough and long-wearing.

2. Picture Film

This is another area where both products utilize the same technology. This is a vinyl film onto which the picture is printed. This film is waterproof and flexible, and perfectly suitable for both products. This is one of the reasons that Hybrid had such a short development period and entered the market so quickly.

3. Core

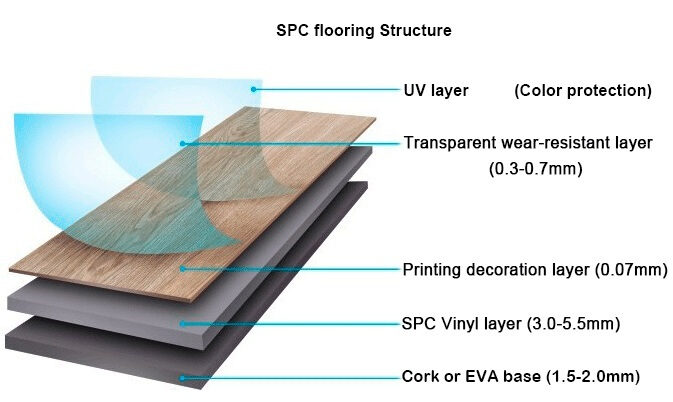

The Core of these two products categories is where they diverge. Vinyl Plank Flooring uses a core made from multiple layers of PVC and Fiberglass. These layers are pressed together in an attempt to stabilize the product. The edges of Vinyl Planks are square, and when they install, they simply sit one beside the other.

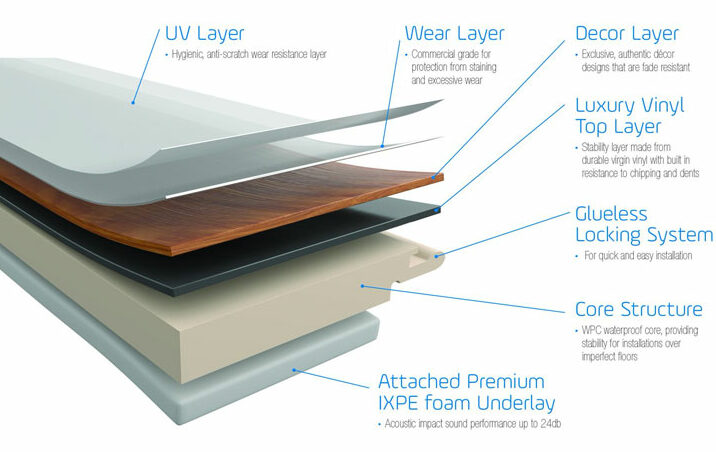

Hybrid Flooring on the other hand (whether SPC or WPC,) uses a rigid core that is made mostly from Limestone and PVC. It has a locking mechanism machined into the sides and ends of the boards, and they lock together the same way as a laminate floor does.

4. Backing

The backing is another area where these products differ. The backing on a Vinyl Plank is designed to allow the adhesive to gain traction to it and bond properly to the floor. On the other hand, the backing on a Hybrid Floor is there for comfort and acoustics. It allows for a certain amount of ‘Give’ under this rigid floor type.

5. Installation

Vinyl Plank Flooring installs by gluing the planks directly to the floor with either a Pressure Sensitive or Hart Set Adhesive. A Pressure Sensitive Adhesive will allow you to replace planks more easily but is less effective at controlling growth and shrinkage due to temperature. Vinyl Planks have the advantage that they can be laid right up to your existing skirtings, and there is no need to remove and replace these, or instead use a Scotia.

Hybrid Planks install by locking planks to each other in the same way as Laminate Flooring. This makes for a glueless installation in the case you do not like working with adhesives. Space down shot of this is that a perimeter raft break is required, meaning that you will either need to remove and replace skirtings or install a scotia to cover this gap.

Both products can be cut by scoring the wear layer with a sharp knife and then bending the product until it snaps. For Vinyl Planks the entire job can be done with a knife, whereas Hybrid will require a Jigsaw for some cuts.

6. Floor Preparation

Both products require a level floor to lay on, and the degree to which is outlaid by the product supplier. The floor level is similar for both products, but for 2 different reasons.

Vinyl Plank will follow all of the contours of a floor, riding high and low points. While there is little if any chance of the floor being damaged if it is not level, the ‘waves’ in the floor will be visible, and over time Vinyl Planks will show any imperfections in the subfloor beneath it.

For Hybrid Flooring the issue is different. Being Rigid, Hybrid ‘bridges’ high points, leaving hollow points in the space between the floor and subfloor. When these points are stepped on, the stress caused transfers into the joins of the floor, and eventually, they will break.

7. Commercial Application

In Large commercial spaces where the floor is intended to be a long term solution, Vinyl is the better product to use for commercial flooring. This is because it glues directly to the floor, and there is no ability for it to ‘bounce’, and it does not require transition breaks for expansion breaks.

For smaller commercial and temporary areas under twenty metres in any direction, Hybrid is the better option as it can be floated, and taken up relatively easily, and there will be no need to grind adhesive from the floor.

8. Acoustic Performance

In the area of Airborne noise, Vinyl is quieter as it is softer underfoot and better absorbs footfall. Hybrid being rigid tends to make more airborne noise.

In the area of Structure Borne Noise, the reverse is true. Most Vinyl Plank flooring fails the BCA requirement for multi-res units living. This is because the vinyl is softer, the energy of your footfall transfers more easily into the subfloor below. Hybrid while rigid, sits on a soft underlay which reduces the transfer of energy into the subfloor. All Hybrid flooring easily passes the basic BCA requirements.

9. Heat Resistance

Being made mostly of PVC, Vinyl does not have particularly good heat resistance. It tends to expand in hot conditions, and shrink in colder ones. This can be controlled to a large degree by using Hard Set adhesive. Hybrid on the other hand is made mostly of Limestone which is much more heat resistant. Therefore, Hybrid Flooring will hold its shape far better in extreme temperature conditions.

10. Water Resistance

Both Vinyl Planks Flooring and Hybrid Flooring are completely waterproof. You can afford to wet mop these floors with complete confidence.

11. Stain Resistance

These floors have the same wear layer and have the same stain resistance properties. Both floors perform very well in this area, but as with everything, speed is the key with things like coffee and red wine, which is likely to cause long-term stains.

12. Burn Resistance

Again, the PVC polyurethane wear layer on these products have the same properties. While they are good with heat, you do not want to have things like hot coals or cigarettes land on the floor.