The hybrid flooring category is in actuality two distinct but similar types of flooring products: WPC hybrid and SPC hybrid. While they both include the name ‘Hybrid’, it is important to view them as separate products.

Here, we’ll cover an in-depth comparison of SPC hybrid and WPC hybrid flooring to help you determine which option will best fit your needs.

What Is WPC Flooring?

WPC (Wood Plastic/ Polymer Composite) flooring features a core typically composed of:

- Calcium Carbonate (Limestone Powder)

- Wood-like or actual wood materials such as wood flour, or bamboo flour

- Polyvinyl chloride (PVC) used as the binding agent

- UV Stabiliser

- A Foaming agent

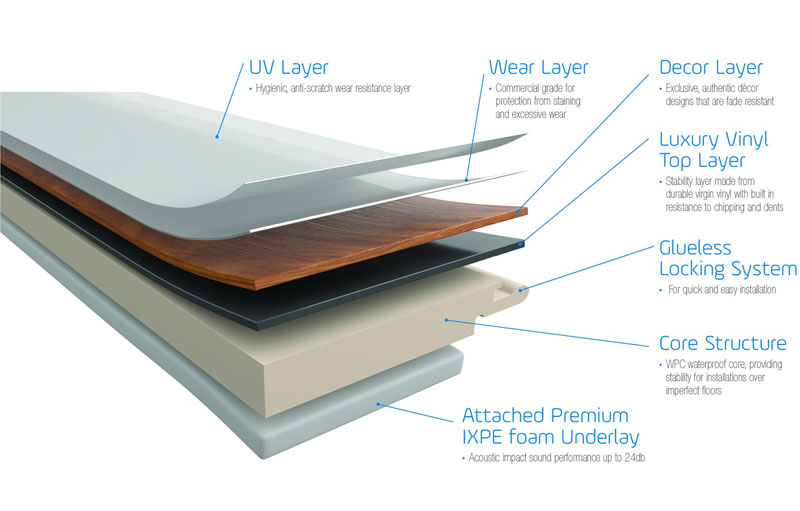

This then has an underlay (foam or rubber,) added to the back of the product, and a small 1.5mm layer of Vinyl to the top, followed by a vinyl picture film and a Polyurethane PVC Wear Layer.

Originally named for the wood-like materials included in its composition, WPC floors first hit the Australian market about 8 years ago. WPC flooring never really gained popularity in Australia as an option for replacing various rafted flooring options until SPC was launched. Then both products were included under the ‘Hybrid’ banner, and often the distinction between them was lost.

WPC flooring is waterproof and shares the same wear layer and picture film as vinyl plank flooring.

What Is SPC Flooring?

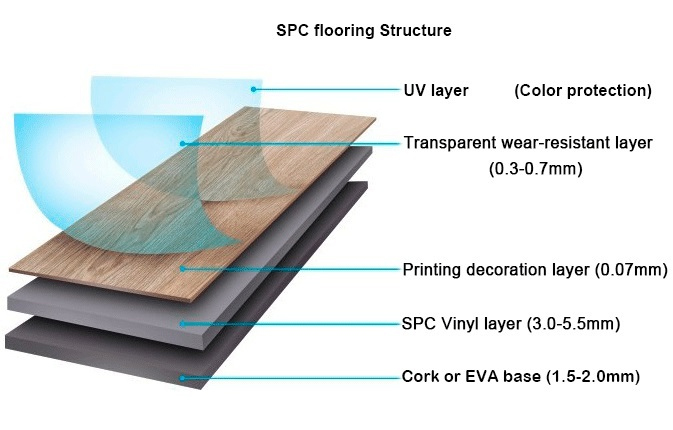

SPC (Stone Plastic/Polymer Composite) flooring features a core typically composed of:

- Calcium Carbonate (Limestone Powder) at least 80% in content

- Polyvinyl chloride (PVC) used as the binding agent

- UV Stabiliser

This also has an underlay (again, either foam or rubber,) added to the back of the product. Then a vinyl picture film is bonded directly to the core, with the same Polyurethane PVC. Unlike the WPC, there is no need for the layer of vinyl between the Core and the Picture Film.

SPC hybrid flooring hit the market about 3 to 4 years after WPC flooring and has quickly gained popularity thanks to its durability, dependability and quality. In the last 3 years, SPC Hybrid Flooring has become the number one Flooring category. Because it lacks the Wood and Bamboo Flour, and the Foaming Agent of the WPC, it has a more solid and stable composition and better resists temperature change.

SPC flooring, like WPC flooring, is waterproof and shares the same wear layer and picture film as vinyl plank flooring.

What Is the Main Difference Between SPC Hybrid and WPC Hybrid Flooring?

The big difference between SPC and WPC hybrid flooring is that WPC flooring includes a foaming agent through the core. This causes WPC hybrid flooring to be filled with tiny microbubbles of air throughout the entirety of its core.

What Does the Foaming Agent in WPC Hybrid Flooring Do?

As a result of the foaming agent in its core, WPC hybrid flooring is lighter in weight due to the aeration of the core. Because of this though, it has weaker joints and is less solid than SPC flooring.

Because of the micro-bubbling caused by the foaming agent, WPC flooring cannot have a picture film bonded directly to its core. When these products (both WPC and SPC,) are manufactured, they undergo a process known as ‘Hot Pressing’. The multiple layers of the product are pressed together under an enormous amount of heat and pressure that activates adhesives and binds all of the layers together.

If Vinyl Picture film is hot pressed directly onto a WPC core, the pressures involved will ‘Press’ the picture film into the microbubbles of the core, and will cause little micro-dimples to be visible in the picture. While you cannot see the dimples directly (due to their size,) they give the product a lacklustre look that makes it look washed out. To prevent this micro-dimpling, WPC hybrid floors have what looks like a 1.5mm vinyl plank bonded to the top of the core to give the vinyl picture film support behind. This prevents the transference of these Microbubbles into the picture film.

Heat can also cause the aerated core of WPC Flooring can also cause the tiny microbubbles to heat and expand, which in turn causes the product to grow. This limits WPC flooring to smaller applications unless you use expansion breaks in the floor. For example, if you have a room that is over 10 metres in length or width, you will need at least one expansion break on a WPC floor. SPC Flooring in most cases can go up to 20 metres in either direction before an expansion break is required.

Not found

Which Is More Expensive: WPC or SPC Hybrid Flooring?

In terms of the cost difference between WPC and SPC hybrid flooring, they typically come out about the same. WPC hybrid flooring is more labour-intensive because of the additional elements and processes required in its manufacture. SPC flooring is more product intensive because it is a solid core product, with more Calcium Carbonate used in its production.

Which Is Thicker: WPC or SPC Flooring?

We are often asked about the thickness of hybrid flooring. The common preconception is that thicker is better. While this is usually the case, the WPC and SPC categories must be compared separately as a 6mm SPC floor will be stronger than a 9mm WPC Floor!

While a section of WPC flooring may be thicker than an SPC plank, it will usually still fall short of the strength of the SPC flooring due to the foaming agent used in the core of the product. The best way to think of this is that the WPC Floor is like an ‘Aero Bar’, and the SPC is your solid ‘Full Cream Dairy Milk’ Chocolate. They are both made of very similar things, yet the Full Block of Aero bar weighs 115 grams, whereas the Solid Chocolate equivalent in the same Volume weighs 180 grams. The one thing that was different between these two products is ‘Air’.

Hybrid Flooring is much like this. Most WPC planks need to be at least 8mm thick or more to make up for the aeration within their core. SPC hybrid flooring can be only 6mm thick and boast superior strength to 8mm thick WPC flooring.

For SPC flooring, the magic number tends to be between 6mm and 7mm in thickness. This is because while SPC is very hard, it can be a little brittle when it is thinner in format. Additionally, having less weight in the core can cause the product to be a little unstable in cases of prolonged exposure to direct extreme sunlight.

As an example, a Hybrid of 7mm will typically have a core weight that is 50% greater than a hybrid of 5.5mm from the same supplier using the same cubic metre core weight. This gives the product joins that are much stronger (each half a millimetre makes a difference,) and gives it greater stability and elemental resistance.

Is Thicker Hybrid Better?

In general, this is the case, but there are some unexpected cons to consider when it comes to a Hybrid’s thickness. While thicker a product offers greater strength and stability how much more than enough is required? Anything above 7mm thick makes the product heavier, causing transportation more to be far more expensive. For example, if a 7mm Hybrid weights 10kg per square metre, a 9mm Hybrid will typically be 13-14 kg per square metre.

Therefore the cost to benefit ratio must be looked at here: is the extra security over and above what is required worth the additional cost? However, heavier Hybrids sit on the floor better and the extra weight helps create friction on the underlay, and prevent movement in the flooring raft.

We would be glad to help you weigh hybrid flooring pros and cons and help you determine the ideal product for your home.

Note: For any rafted (Hybrid, Laminate or Timber) Flooring, regardless of thickness, it is always important to have a level subfloor to prevent damage to the joins.

Thinking of Buying Hybrid Floors?

Great Choice!

Download our Ultimate Guide to Hybrid Flooring and learn everything you need to know to choose the right hybrid planks for your space.

How To Tell the Difference Between WPC and SPC Hybrid Flooring

To instantly know the difference between WPC and SPC flooring, pick up two planks of the same thickness, size, and length. The lighter one will be WPC flooring.

An easier, more simple way is to run your finger down an exposed joint. WPC will feel like light grit sandpaper due to the open-air bubbles in its core that are exposed when the join is profiled into the product. SPC on the other hand will feel completely solid and smooth, even where it has been profiled because it is solid all the way through!

Is SPC or WPC Flooring Better for Commercial Applications?

In Commercial applications, a heavier weight SPC Flooring is preferred for commercial flooring. This is because as a floated floor, it is not bonded to the Sub-Floor underneath, and can move when there are large amounts of people moving on top of it. If this movement happens in different directions, a lighter weight floor can either be pushed together and create peaks in certain areas or pull the floor apart at the Joins.

Therefore, we do not recommend WPC, or lightweight SPC flooring (5.5mm and below,) in any commercial application. For larger commercial applications, consider a Hybrid of at least 8mm in thickness.

So Why is WPC Hybrid Still on the Market?

This may be the question you are asking after reading this. The simple answer is that WPC is an older technology and companies had a large investment in it and need to sell their product. To the uneducated, a story can be told that makes WPC sound great. It is not that it is bad, it is just that SPC is better in almost every way.

As Hybrid gained Traction in the Australian market place, it was soon evident that this was the golden goose, and every supplier wanted a piece of the pie. The problem for some suppliers is that they did not have a background across all flooring categories, and when they were looking for a point of difference, WPC in some cases seemed like the answer to them.

For example, in my time with Signature Floors, the Hybrid Development was led by myself and one other person with expertise in hard flooring (Timber and Laminate,) and 2 people with expertise in Resilient (Vinyl,) Flooring. In this process, both sides of the table have expertise that the other side lacked. This caused us to come at the product from all sides, and SPC was the easy answer.

Some companies do not have this cross-pollination of disciplines and didn’t know what they didn’t know. Others had made a large investment into WPC before the advent of SPC, and could not change their direction without a large financial sacrifice. Often they added SPC along the way, but could not get rid of their WPC catalogue entirely.

Do You Have More Questions About SPC or WPC Hybrid Flooring?

If you have further questions, would like to learn more about hybrid flooring pros and cons or would like additional advice on WPC or SPC hybrid flooring, please feel free to contact our team of flooring experts. One of our experienced flooring professionals would be happy to help guide you through the entire process, help you decide on the best flooring type for your needs, and make the experience of buying flooring as seamless as possible.

Frequently Asked Questions About Hybrid Flooring

Let me break this down with a chocolate analogy I often use: Think of WPC like an Aero bar and SPC like a solid Dairy Milk; they're made of similar ingredients, but one's full of air bubbles. While WPC is more labor-intensive to manufacture (needing that extra vinyl layer to prevent dimpling), SPC uses significantly more raw materials because it's solid all the way through. In fact, SPC needs at least 80% calcium carbonate content, making it heavier and more material-intensive. That's why they end up costing about the same, despite SPC being "simpler" in composition.

Here's an industry secret a 6mm SPC floor can actually be stronger than a 9mm WPC floor! It's not about thickness, it's about density. Think about it this way: would you rather walk on a 10mm thick foam mat or a 5mm solid rubber mat? For SPC, the sweet spot is between 6-7mm. Going thicker than 7mm just adds weight (and shipping costs) without significant benefits. However, if you're looking at WPC, you'll need at least 8mm thickness to match the strength of a 6mm SPC because of all those micro-bubbles in the core.

After years in the industry, I'll tell you straight SPC is your best bet for large spaces, especially those with direct sunlight.

Here's why:

WPC has those micro-bubbles in its core that can expand with heat, meaning you'll need expansion breaks every 10 meters.

SPC, being solid, can typically go up to 20 meters without breaks. Plus, those air bubbles in WPC make it more susceptible to temperature changes, which is crucial in sun-exposed areas.

For large commercial or open-plan residential spaces, I always recommend a heavier SPC (at least 8mm) as it'll sit better and resist movement under heavy foot traffic.