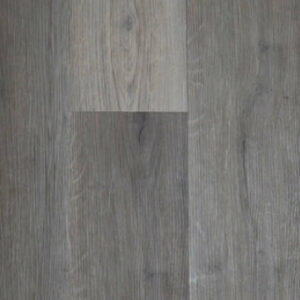

WPC and SPC are 2 different types of Hybrid flooring that have a lot in common. WPC technology was first created for composite decking, and the product eventually made its way into flooring. SPC is a later development and improvement upon the older WPC and solved a lot of WPC’s inherrant issues.

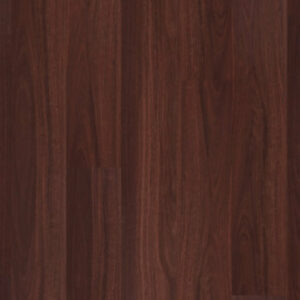

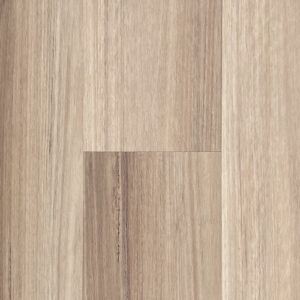

WPC Flooring originally stood for ‘Wood Polymer Composite’ even though now there is no wood in the product that has been used for Flooring. The original WPC was developed as a decking material for external use, which made it an excellent concept to be developed as a flooring category, which it was. WPC is made predominantly of limestone powder and PVC, but has a foaming agent added to the mix, which aerates the product and gives it a relatively light weight. It was waterproof, easy to install and was easily able to utilize existing Vinyl plank picture films and wear layers.

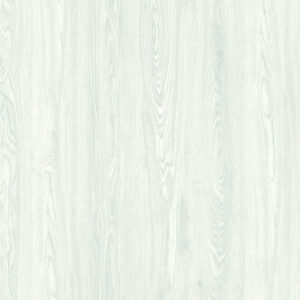

Due to the aerated nature of the WPC core, you will notice that all WPC flooring has an almost sandpaper like feel when you run your finger down the join. Because of the aerated nature of the core, the product is honeycombed on a micro level, meaning that a picture film cannot be bonded directly to a WPC Core, otherwise ‘micro-dimples’ will show through into the picture when the layers of the product are pressed together. To overcome this issue, a thin layer of Vinyl plank flooring is laminated to the top of the WPC core which in effect gives the picture film a flat surface to bond to.

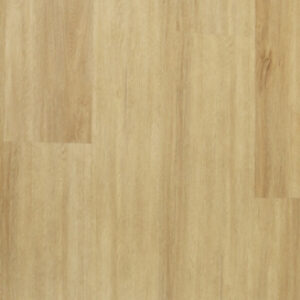

The Aeration of the core however is the greatest weakness of WPC flooring, as the honeycombed nature of the product makes the joins inherently quite weak and pliable. Additionally, at greater temperatures, the air bubbles within the core become hot and expand causing mush greater expansion than an SPC Hybrid Floor. Because of this, WPC floors can usually only be laid in ¼ of the volume of an SPC floor before the floor needs to be compartmentalised into Separate rafts.

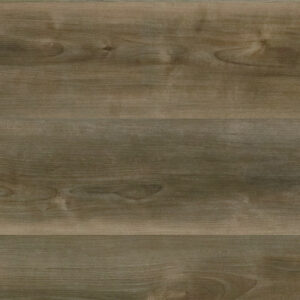

SPC Flooring is a later development that uses a solid core that does not contain the foaming agent that is present in WPC. While each manufacturer uses a different ‘Recipe’ for their core, SPC has a higher limestone content than WPC Flooring does: usually 80% or more. Because SPC does not have a foaming agent added, it is solid, and not honeycombed like WPC Hybrid is. This has several benefits.

Firstly, because the core is solid, SPC can have a picture film bonded directly to the core. This means that while SPC more expensive in terms of the material costs, the manufacturing cost is less, meaning that the costs of the products are about the same. Additionally, because of the solid core, the joins on SPC are much stronger, and the volume of flooring that can be laid before the floor needs to be compartmentalised is about 4 times that of WPC Hybrid before there needs to be any expansion breaks!