Have you ever been in an apartment where it sounded like a bowling competition was going on above you? Or walked into a business and heard your every step echo through the room?

These problems can all improved by choosing acoustically-friendly soundproof flooring. Here, we’ll cover the best soundproof floors and how to improve the noise level of your current flooring.

The question is a frequently asked one, and with the rise in multi-res apartment blocks in urban areas, it is becoming more and more of an issue within the flooring industry. To understand the answer to this question, we must understand that this is 2 questions: What floors are best for minimizing Air Borne noise, and what floors are best at minimizing Structure Borne noise?

Within this Blog, we will look at these 2 different kinds of noise and how are they attenuated.

What Are These Different Types of Sound?

Air Borne Noise and Structure Borne Noise both affect you through the displacement of Air. However, they are generated in Slightly different ways.

- Air Borne Noise is the noise that you normally hear directly from the source while it is unobstructed. When you knock on a door, you and anyone on your side of the door hear this noise as Air Borne Noise.

- Structure Borne Noise is the kind of noise you hear as vibration energy travels into an object, transferred from an airborne state and vibrates the object. This Vibration then affects the air on the other side of the object and is converted into Noise. While the noise is generated through the air, it is caused by the vibrating of the solid medium and is hence termed Structure Borne Noise. If someone on the other side of a door to you knocks on the door, you and anyone on your side of the door hear the noise as Structure Borne Noise.

While both of these kinds of noise are heard through the displacement of air, they are caused in 2 different ways. The Airborne noise is direct from the Primary source of the sound, where Structure Borne Noise is caused by Secondary Sources.

Home theatres benefit from having quality soundproof flooring.

What Are the Different Sound Ratings?

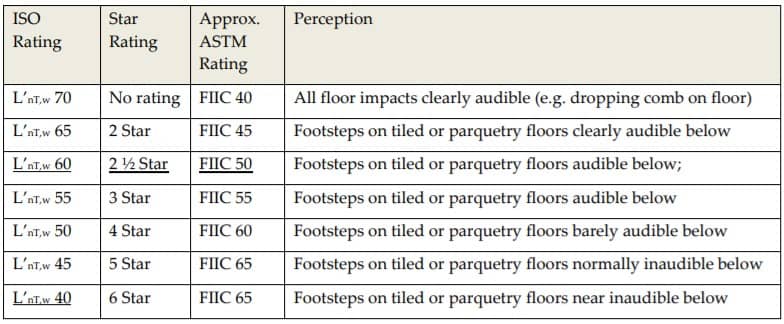

There are 3 main different sound ratings in use in Australia. The last rating has mostly passed from use in Australia but is still recorded in Old Body Corporate Bylaws. As many Bylaws are ‘Cut and Pasted’ from one building to another, it is still in common use in older buildings, but no longer used for new documentation in the Building Code.

- Rw or Weighted Sound Reduction Index is used to measure how much an object can reduce the leakage of Air Borne Noise. The Rw Rating directly becomes the reduction in dB (decibel) measurement that the attenuator creates. For Example, if a piece of Plasterboard reduced the Sound Level by 25 dB, it would be rated as 25 Rw.

- LnTw/Ln,w both measure Weighted Impact Sound Pressure. LnTw is the rating used in Field Tests, and Ln,w is used for controlled lab tests, but they measure in the same way. Weighted Impact Sound Pressure tests measure the sound pressure after the noise has been attenuated. Where Rw measures the reduction provided by the isolator, this test measures the sound after reduction has occurred. LnTw/Ln,w correspond directly to dB ratings. Therefore, if the result of the test is LnTw 54, the test measured 54dB of Sound Pressure. Combining the 2 ratings, if a base noise of 70db was attenuated by a 25 Rw Isolator, it should measure as 45 LnTw.

- IIC/FIIC stands for Impact Insulation Class and Field Impact Insulation Class respectively. As with LnTw and Ln,w, IIC is the lab test result and FIIC is the result of a site test. This rating measures Sound Reduction in Decibels but is harder to understand than the other 2 ratings so it has fallen out of use. The higher the IIC/FIIC rating, the greater the sound reduction in dB. Because this test is measured differently from the Weighted Sound Isolation Test, there is no direct crossover between the 2 tests. There is a rough method of calculation, but it is not an exact science, so we won’t go into it. The reason that IIC and FIIC are still used at all is because of old Body Corporate bylaws.

The most commonly used ratings for flooring and LnTw and Ln,w.

How Does All of This Work?

When we look at the LnTw/Ln,w ratings, we are looking at the dB level to which they reduce the sound of human footfall.

This chart shows us in terms of LnTw, FIIC and the Star Rating how to make the comparison.

The BCA (Building Code of Australia,) with regards to structure Borne Noise Transmission states:

“An LnTw + CI not more than 62 for floors separating dwellings and for floors separating dwellings from a plant room, lift shaft, stairway, public corridor, public lobby or the like, or parts of a different classification.”

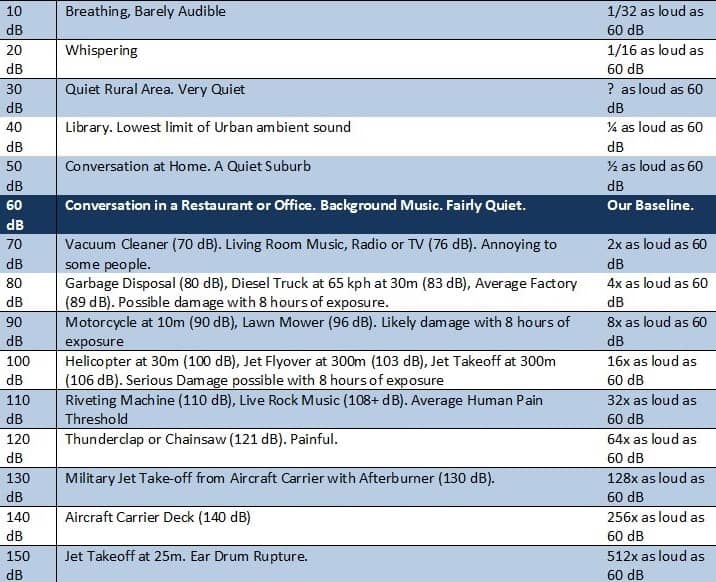

In the Above, the ‘+CI’ Stands for a ‘Corrective Indicator’, and we need not worry about this too much. If we then look at what 62 dB looks like, it is the sound of human conversation in a public place, the range of which is 60-65 dB.

Using a dB rating of 60 as our base, you can apply the following rule of thumb:

“Every 10 points in the increase of dB doubles the Sound Pressure. Every 10 dB reduction in dB halves the Sound Pressure”.

This chart shows what sound starts to look like as we increase and decrease sound level, still using 60 dB as baseline.

While much of this information is unlikely to affect you in everyday life, it is interesting as a point of Comparison. What this means though is that when people are walking around above you on a Vinyl Plank Floor, you will likely experience the same level of sound as a fairly loud conversation happening in the same room as you. A Hybrid Floor however in many cases will sound more like being in a Library.

How Are Air-borne and Structure-borne Noise Different?

Let’s have a deeper look at this now. Air-borne noise as its name implies is Noise that is borne through the displacement of air. When you make a noise of any kind, it is the movement of air reacting with the inside of our ears that creates what we experience as ‘noise’. If a tree falls in the forest does anybody hear? If we did not have ears, we would not hear this noise, but if the movement of air was large enough, we are capable of feeling this noise.

Structure-Borne noise ends up becoming Air Borne noise through a process called ‘reradiation’. This is a vibration travelling into an object, and this movement of the object creates a pulse of air on the other side, which transfers into Air Borne Noise. However, as it has first had to travel as vibration energy through a solid medium, it is referred to as structure-borne noise. This is normally measured with the LnTw/Ln,w or IIC/FIIC ratings.

The easiest way to think of this is to imagine you and I are on opposite sides of a wall. Pretend you are on the inside of a house and I am on the outside. I can yell, and I can hear myself quite clearly. However, let’s assume that your house is locked up and you really can’t hear me.

Then I walk up and knock on your door. My knuckles rap against the door, and I hear that noise as Air Borne Noise. My knuckles hit the wood of the door, the air is displaced and you hear the noise as Air-Borne Noise. The experience for yourself on the other side of the door is different. I have rapped on the door, but what you are hearing is the impact of my knock travelling through the solid structure of the door. This vibration ‘reradiated’ on the opposite of the door, displacing the air here, and you hear it as Structure Borne Noise.

Because these 2 kinds of noise are generated in 2 different ways, they must be approached differently.

How Do Air Borne and Structure Borne Noise Affect Me?

This will depend on your living situation. If you are in a suburban, single-story home, you will experience very little in the way of Structure Borne Noise that will affect your daily life. Maybe occasionally just the ‘Doof Doof’ of a neighbour’s stereo as the low-end noise makes its way through your walls!

Alternately, if you are living in a multi-story residential complex, Structure Borne Noise is going to be the bane of your existence. If you live in a multi-level home, but it is your dwelling that is not shared with others, then you may find you are affected by both.

The NFD Soundless range is ideal for home libraries or multi-storey apartment block.

How Do I Deal With Air Borne Noise?

Airborne Noise is reflected from large, hard objects. This means that hard flooring on its own can act as a kind of reverberator for Air Borne Noise. The best kind of Floor Covering to attenuate Airborne noise is Carpet. Because it is soft, you do not hear your footfall. It also absorbs high-end frequencies, so helps to reduce refractive noise. If you have hard flooring in your house, soft window coverings will make a large difference in sound deadening, as well as rugs and other soft items like cushions, couches and chairs with fabric coverings.

After Carpet, the next best floor covering for Airborne is Vinyl Flooring, either in a plank or sheet format. Because the product is less rigid than other hard floor coverings, it better absorbs footfall and creates less in the way of Airborne Noise.

While not as soft as Vinyl, and made predominantly of Limestone, Hybrid Flooring is fairly good at keeping noise levels down as well. This is because the substance that binds the limestone powder together is PVC. PVC is flexible and therefore has a certain amount of ‘Give’ underfoot.

After this, Bamboo, timber and Laminate floors are all far noisier, because in each case, these floors have rigidity and rigid mediums vibrate and hence reflect more noise. Think of the difference between the sound of a guitar string that is strung tightly onto a guitar and one that just sits loose off of the guitar. When agitated, they react very differently and this is due to tension and rigidity.

If you have a hard floor like Timber, Bamboo or Laminate, a denser underlay will help to absorb some of the energy that is created when you walk on the floor. The denser the underlay, the greater its ability to absorb some of this Air Borne Noise. However, always use an underlay recommended by the product manufacturer and never use something that they advise against.

For example, after reading the above, one could be tempted to put a nice soft carpet underlay under a timber floor, thinking that this thicker underlay will give a greater level of sound deadening. This however is completely the wrong thing to do, as the additional movement under the floor caused by a thicker underlay that is lower in density would in a very short time cause major damage to the joins on the floor.

How Do I Deal With Structure Borne Noise?

Structure Borne Noise is mitigated in a couple of different ways, and this is the Under and Over Approach. The Under Approach is what happens under the sub-floor, and is typically something that happens in a unit beneath where you are installing the floor. As this has little to do with what can be controlled by Floor Coverings, we won’t get into it too much here.

The Over Approach is what sits under your floor but over the sub-floor. This is the underlay that you have under a rigid floor covering. There are several balances to be struck here and we will have an in-depth look at these and how they affect you. Carpet usually does not require any special treatment as it is already soft and sits on a soft underlay. As a result, carpet is the best isolator of structure-borne noise. However, carpet is more and more being replaced with hard and resilient flooring because of its durability.

Under Hard and Vinyl Floors different underlays can be used to attenuate the vibrational energy that will be converted into structure-borne noise. This is achieved through a process known as Static Deflection. Static Deflection is achieved by the isolator (in our case the underlay,) being compressed by the weight of a load that is placed on top of it (in our case the floor,) and as the vibrational energy tries to make its way through the compressed medium, a percentage of the energy is lost, dependent upon the kind of Frequency. High Frequency is very easy to attenuate, whereas Low Frequency is notoriously difficult to attenuate.

Typically, the more Static Deflection the better. This means that the more that your underlay is compressed the better it is to mitigate structure-borne noise…. to a point. There is a point at which a product is compressed so much that it flattens out and is no longer effective.

There is another issue that must also be considered in this equation and that is if a product deflects (compresses,) under load it mitigates vibration energy. However, a product that deflects too much under load can cause real damage to the floor on top of it.

For example, let’s say that a standard 2mm foam underlay (33kg per m³ density) for laminate flooring will compress 1mm when you walk on it. This is a 50% compression rate. If the underlay were the same density but was 10 mm thick, the underlay would compress 5mm, because your weight causes 50% compression with that density of underlay.

This would be very bad for your floor, as 5mm of deflection will be to your floor like repeatedly bending a piece of wire backwards and forwards. It will soon snap. This will happen on the weakest areas of the floor, which are the joins.

In the case of underlay for floating floors, this is not an issue you need to be concerned with as these are designed specifically for the job that they do in a 2 or 3mm foam. Some are closed-cell foams, and others are open-cell foams. Closed-cell will hold their shape for a long time. Open-cell will not and will after time be like having a sheet of paper under the floor.

As mentioned, the compression rate will affect the amount of vibration energy that will be mitigated by the underlay. It is for this reason though that most of the cheaper Closed Cell Foam Underlays will outperform their Higher density Closed Cell Foam and Rubber Underlays that are marketed as ‘Acoustic’ underlays.

For example, an underlay that is 33kg per m³ in density that compresses 50% under your footfall will only compress about 25% if the underlay was 66kg per m³, and around 13% if the underlay were 125 kg per m³. If the underlay were 200kg per m³, it would make a great sales pitch (because we all think bigger is better,) but would be of little acoustic value. However, having said this, these higher density underlays tend to perform better for Airborne Noise.

In a previous role, I worked for a company that had the only Vertical test facility in the country outside of the CSIRO. This meant we were able to (and often did,) test our and competitor’s products side by side. At that stage, we had our standard underlay (33kg density,) our Acoustic Underlay (66kg Density,) which were both closed Cell Foams, and our rubber underlay in a 750-800kg density.

To be honest, the density of the rubber makes it look like it will not be of any value, but it is a different consistency and works differently from the foams. In this test, the product that performed best was the humble little 33kg density underlay, followed (closely) by the Rubber, and then the 66kg density Acoustic Underlay.

What Are the Best Kinds of Flooring for Reducing Sound in a Room?

Carpet and Carpet Tiles are great natural attenuators of Noise for a room. They are soft, so they do not create noise, they are also great for not creating Structure Borne Noise and soundproofing floors. Additionally, it helps to reduce the noise caused by other sources. Carpet though is the least durable type of floor covering, and in the last 20 years, the amount of carpet sold in Australia has reduced by a great degree, and been replaced with hard and resilient floor coverings.

Luxury Vinyl Plank (LVT or LVP) is soft and flexible compared to other types of Hard Flooring, so does not create much in the way of Airborne Noise. However, for Structure Borne Noise LVT is not a great option, as there are very few that meet the most basic Building Code Requirements for Multi-Res buildings. Some underlays can help with this, but this then lifts the cost of LVT Flooring.

Hybrid Flooring is in every way the great all-rounder. While not as quiet as LVT Flooring in the Air Borne capacity, it far outclasses it when it comes to Structure Borne Noise. Without needing any other form of attenuation in most cases, Hybrid generally outclasses all other hard Flooring Types in the realm.

Laminate and Timber Flooring make the most Air Borne Noise, but as they are almost always laid on Underlay are pretty good with Structure Borne Noise. If you are planning to Direct Stick Timber Flooring, the standard underlay that is used to float floors on is not used but is instead replaced with a high-density Shredded Rubber underlay, that allows you to bond the product in a process known as Dual Bonding.

Carpet tiles reduce noise in highly trafficked areas such as office or a reception area.

Tips for Reducing Noise on Existing Flooring

There is not much that can be done to Flooring that is already in use to help reduce noise, but there is plenty that you can do around your living space that will help.

Rugs are a great place to start as they absorb a lot of sounds that bounce around from wall to wall. In the same way cushions, pillows and even soft toys. Individually, they do little, but as more are added, they combine to significantly reduce refractive noise.

Another thing that can make a big difference is curtains. Curtains will significantly reduce refractive noise, and they are great because they can cover a large surface area when they are in their ‘Closed’ State. Even when they are open they are a big help.

Frequently Asked Questions About Soundproof Flooring

This is one of the trickiest aspects of acoustic flooring because many older buildings still use IIC ratings in their bylaws, even though Australia has largely moved to LnTw ratings. While there's no exact conversion (which is partly why we moved away from IIC), here's a practical way to think about it: if your Body Corporate requires an IIC rating of 55, you're typically looking for an LnTw rating around 50-52.

But here's my strong recommendation - always get this confirmed in writing before proceeding, as interpretation can vary between buildings.

From years of acoustic testing experience, I can tell you that hybrid flooring is your best bet for hard flooring. Here's why: while luxury vinyl plank (LVT) might seem softer and quieter for airborne noise, hybrid flooring significantly outperforms it for structure-borne noise; that's the footfall noise your downstairs neighbour's hear.

Most hybrid products meet basic Building Code requirements without needing additional acoustic underlays, whereas with LVT, you'd often need to add expensive acoustic underlays to achieve the same result.

While you can't change the acoustic properties of already-installed flooring, you can significantly improve your room's acoustics with strategic additions. Strategic placement of rugs is your best immediate solution - they're particularly effective in high-traffic areas like hallways.

But don't stop there, curtains are surprisingly effective at reducing refractive noise (even when open), and soft furnishings like cushions and upholstered furniture all contribute to noise reduction. Each soft item you add combines with others to create a cumulative sound-dampening effect.