Last updated 22/4/24

If you have ever enquired about Timber flooring. There is a good chance that no one has talked to you about acclimatising the product before you have it laid on your floor. To say that the issue is important is an understatement. It is a critical and possibly the most crucial consideration for acclimatising your timber floor.

In this blog, we will cover why having your floor acclimatised before installation is essential. It will be heavily laden with maths and science. If this is not your thing, smile and nod along. We did our homework!

Overview:

- Why is Acclimatising Flooring So Important?

- Why is It Missed at the Point of Sale?

- Timber Flooring as a Specialised Field

- Important of Acclimatisation

- How to Find Information

- How Does It All Work?

- Is It Always the Same?

- Let’s Try an Example

- How Does This Make My Floor Grow and Shrink?

- The Elephant in the Room

- How Long Do I Let My Floor Acclimatise?

- Breaking the Rules

Why Acclimatising Natural Flooring Is Important

Admittedly, Australia has a huge climate variation across states and seasons. Although some areas, like far north Queensland, may be more hazardous to humidity and moisture, all areas in Australia will require flooring to be acclimatised prior to laying.

Every type of natural flooring grows and shrinks with the seasons as it both takes in and releases moisture. As the humidity increases, the floor takes in moisture and grows. As the humidity drops, the floor releases moisture and shrinks. This is not an immediate thing and is dependent upon many factors.

- You will have experienced this in other areas of your life. For example, have you ever noticed at times when it is overly humid and some of the doors in your house become difficult to close? Well, this is the same principle in action.

- Every natural flooring type has a midrange or ‘Happy Place’ as we refer to it. This is when the flooring has reached equilibrium with your environment.

This sounds pretty, but what does it mean?

The flooring reaches Equilibrium by either taking in or releasing moisture until it equalises with the environment where it ‘lives’. This does change from season to season, but there is a ‘Happy Place’. This is a point of balance between the seasons. This is where your floor is at its happiest or most stable relative to the environment.

As we go forward, there will be three factors you need to remember to understand where the flooring meets equilibrium with its environment.

- The Relative Humidity (RH) of your environment….

- …combined with the Temperature (T) will determine the….

- …Environmental Moisture Content (EMC) of your flooring.

Don’t worry too much about this now; remember these three terms, and we will return to them later.

Expert Insights From Clem Sturgess

20+ years' experience in hard flooring

Personally, this topic brings a lot of heartache for me from consumers. Typically, I have been the person people have contacted after they have made a mistake with their suppliers and installers regarding needing to leave more room for flooring products to expand and contract. They have had the floor laid but need to understand the area's climate fluctuations and the product's ability to expand. Either could be to blame, but there is often a communication breakdown or difference in opinions between the supplier and the installer. If raft sizes are too big, excessive expansion can result. When growth has nowhere to go, it can only press upwards.

For a consumer, the bottom line is: Listen to the experts. If their solution fits your immediate timeline, accept there is a good reason for it, as explained in this post.

Why is It Not Discussed at the Point of Sale?

The simple answer is that salespeople do not understand this in a more significant percentage of flooring stores. Everyone knows floors grow and shrink, but no one bothers to learn why and how.

When I started in the flooring industry, it was at a time when people were still trained by their employers. I came into the industry fresh and was taught about vinyl, carpet, timber, laminate, tiles, blinds, floor preparation and anything else I had missed. It was just a part of the process; if you didn’t take it all in, you didn’t stay in the job.

The world has changed dramatically in the last 20 years, and the Flooring Industry has not been immune to this change.

A Need for No More Gaps in the Timber Flooring Industry

Once upon a time, you might go to a flooring store and be served by someone in their middle to senior years. But now, the industry is inhabited by a larger percentage of younger people. This isn’t to say young people can’t provide fantastic customer service because some do; however, the thirst for commission has overtaken the thirst for product knowledge, which seems to be more noticeable in younger generations.

If only they realised more knowledge = more commissions anyway

Manufacturer and labour demands have been progressively sent offshore, making the flooring industry a more appealing career prospect for the unqualified and inexperienced, fueled by the lure of sales commission. Store owners often find themselves short-handed and will often take anyone who can draw a reasonably straight line on a piece of paper and read a tape measure.

As a result, the flooring industry has become woefully under-skilled and thoroughly over-represented. Especially when it comes to floors being adequately acclimatised. This is not to say that the good people aren’t there: there are some great folks. The problem is, how do you find them when you don’t know what you don’t know?

Timber Flooring is a Specialised Field

Having said all of this, Timber Flooring is a highly specialised field and an ‘add-on’ to the carpet shop’s bag of tricks. It is not where their expertise lies. In a world where everyone only wants to sell Hybrid or Vinyl Flooring, this is just a little bit too hard for the Carpet Shop Salesperson.

How Important is Acclimatising?

The short answer is: VERY!

If you were buying a solid timber floor and insisted on the installer laying the product without acclimatisation, he would use fairly colourful language, make several colourful suggestions, and then walk off the job.

That is how serious the issue is, yet it is rarely if ever, discussed in the environment of many retailers.

In many ways, the carpet store salesperson is safeguarded by the fact that they only really sell engineered timber, and the nature of this product means that it will grow and shrink between 3 and 4 times less than solid timber. However, this does not mean that the issue can be ignored. In my time in the Timber Flooring wholesale business, I saw people’s dream floors quickly become nightmares. Simply because the people who sold the product knew no better.

Expert Insights From Dean Billett

28+ Years of flooring industry experience

Allimatisation is critical for solid timbers and will cause significant problems if not done correctly. A product can only move up if it has nowhere to move horizontally.

I recommend waiting at least two weeks for solid timber to give a fair chance of acclimatisation. Stack the boards in the room they are being laid in, and be sure to open the ends of the boxes. Many floor layers say you can wait less than two weeks for engineered timber. However, we still recommend more than two weeks to be safe.

Vinyl planks and laminate are meant to be acclimatised at least 24 hours before being laid, and this can be hard to coordinate and something to keep in mind if the floor layer is also picking up the product intending to apply on the same day.

SPC hybrid planks don't need to be acclimatised becuase their core reduces their ability to expand.

Finding the Information

This is not an easy question to answer and requires a level of Self-education. The Australasian Timber Flooring Association (ATFA) has done some excellent studies into how weather conditions affect timber flooring, and this is a great place to start.

Many years ago, when I first realised the need for an industry-wide understanding of this process, I sought out some of the best timber installers in the business. I began by asking them for some mathematical code behind this all but found that their knowledge was purely intuitive. They were always right in what they knew, but there was no way to codify that knowledge in a way for others to understand without their years of experience.

A great example of this is an installer who, when I asked about how he plans his installations in certain conditions. He told me that he looks at the state of the trees and grass, or lack thereof, and plans for floor growth or contraction accordingly. When I asked him if there was some sort of mathematical code to be used in typical trade speak, he replied: ‘I don’t know any of that s#%t.’

This did not help me prove anything to the customer, so I dug into the subject as much information as possible. Through the hard work and lateral thinking of many people far wiser than myself. I found that there was a way to predict how a floor would react in a particular environment. I was able to write a programme to use in predicting growth and contraction in timber flooring based on the three key factors mentioned at the beginning of this blog:

- (RH) Relative Humidity

- (T) Temperature

- (EMC) Environmental Moisture Content

The basis of this programme came from the information published by ATFA, and I would be remiss if I did not say that this is their information, not my own. I worked out the mathematical formulae and correlated them to weather data.

There is no shortcut to this system. If you are going to get clever with this, you need a great deal of knowledge on the subject. But, for the most part, as we will outline at the end of the blog. Some very simple things can be done to ensure that your floor has the best chance of making it through the season hassle-free.

How Does It All Work?

It is just maths.

X + Y = Z…..right?

But if we don’t know what X or Y is, how do we know how to get to Z? let’s go through the darkness and get to the light at the end.

As we have mentioned a couple of times (by design) in this blog, there are 3 things you need to know: RH, T and EMC. Again Relative Humidity (RH), Temperature (T) and Environmental Moisture Content (EMC).

The RH and T are factors that affect a product’s EMC. The EMC a product wants to be at depends on the RH and T of that environment. This is an ever-changing thing and is not static. However, given that Timber Flooring does not immediately acclimate, we are more concerned with averages than daily or hourly fluctuations.

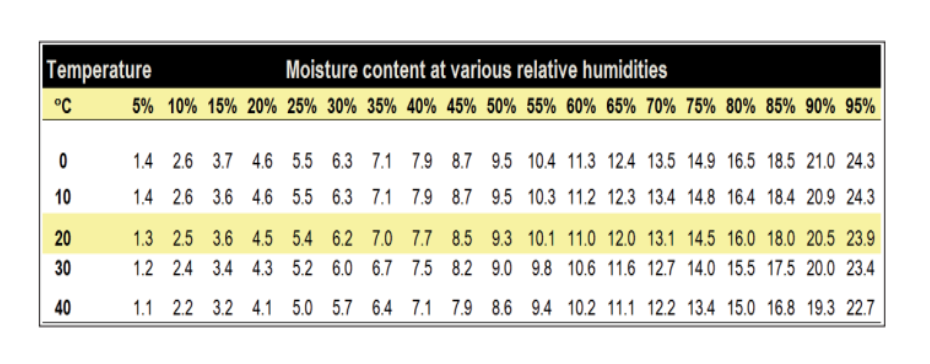

The RH and T directly tell you what EMC a product will rise or fall to in a given environment. Using the chart below, we cross-reference the Relative Humidity across the top with the Temperature down the side to show us what the ‘Happy Place’ for our floor is.

Is It Always the Same?

Weather is a fluctuating and unpredictable thing, but we can determine averages, and this is what we are most concerned with. However, in addition to the yearly averages, we also need to know the yearly highs and yearly lows. Again, these numbers are averages, and we pick the month with the highest averages and the month with the lowest averages. This way, we know where the floor likes to be, and from there, where it will rise to and where it will drop to.

To find this information, timeanddate.com is a site that lets you access any weather tower in the country and allows you to access all of this information from these towers.

Let’s Try an Example

So, we have some idea of how to use this information. Now we just need to choose an area where we are going to install our floor. Let’s choose Sydney as it is the most populous city in Australia.

|

Sydney has a yearly Average RH of 68% at 18°C. According to the above chart, when we cross reference these two numbers, we find that the happy place for our flooring is about 13% EMC. |

|

Sydney has a Yearly high EMC of 73% in February at 23°C. This gives a high EMC of about 14.3%. In August, the RH falls to 61% at 14°C for an EMC of around 11.1% |

|

From the point of view of our floor, notwithstanding extreme weather conditions (which do occur,) our floor is happiest at 13% EMC, rising as far as 14.3% EMC and falling to a low of 11.1% EMC. |

How Does This Make My Floor Grow and Shrink?

Again, in the article by Mr David Hayward, we can see that for every 5% change in EMC in a product, the product will grow or shrink a certain amount per metre of width and length on the floor. The amount the floor will grow with the EMC change depends upon the product’s construction. To keep this reasonably simple, we will look at only the most common types of natural flooring:

|

Engineered Block Core Timber |

Changes by 4mm per 5% change in EMC per metre of flooring |

|---|---|

|

Engineered HDF Core Timber |

Changes by 2mm per 5% change in EMC per metre of flooring |

|

Engineered Hardwood Ply Core Timber |

Changes by 6mm per 5% change in EMC per metre of flooring |

|

Solid Bamboo Flooring |

Changes by 10mm per 5% change in EMC per metre of flooring |

With our Happy Place being 13% EMC, we have a differential of +1.3% at the most humid times and -1.9% at the lowest period.

How This Translates to Growth

Assume we have a 10m long and 6m wide flooring run.

We make this assumption because this is the maximum that most companies will allow the ‘Raft Size’ of a floor before it requires an expansion break. Also, depending on the product, most natural products want to grow more on their width than on their length, as this is how the growth rings work in trees. Therefore, we will just look at the growth in the width of the floor as the length becomes a little more complicated. The point will be made, though.

So, with our Raft being 6m wide, we know that:

|

Engineered Block Core Timber |

Will grow 6.24mm during the high RH period and shrink 9.12mm during the low RH period. |

|---|---|

|

Engineered HDF Core Timber |

Will grow 3.12mm during the high RH period and shrink by 4.56mm during the low RH period. |

|

Engineered Hardwood Ply Core Timber |

Will grow 9.36mm during the high RH period and shrink 13.68mm during the low RH period. |

|

Solid Bamboo Flooring |

Will grow 15.6mm during the high RH period and shrink 22.8mm during the low RH period. |

These numbers represent movement in either direction from the Happy Place.

Also, remember that this is total growth, and it is moving away from the centre of mass of the floor. Therefore, we halve these numbers to look at growth or shrinkage on either side of the floor.

Most suppliers ask for a 12mm expansion gap around the floor’s perimeter or more for high humidity environments. Given that we halve the numbers above, everything looks OK, except possibly Bamboo, which is starting to look sketchy as far as contraction I concerned. This can, however, be alleviated by undercutting your gyprock and installing your flooring in line with the wall. Then your skirting or scotia will give you the buffer you need in either direction.

So we are all good…right? Maybe. But probably not.

The Big Fat Elephant in the Room

All of the above is true if the floor is laid in its Happy Place. But this is rarely the case, so suppliers only account for expansion and never contraction.

But why?

When a typical manufacturer makes a product and packs it overseas, it is usually prepared to a level of between 7-10% EMC. This product then travels here in a container to the warehouse, where it sits until it makes its way to your home. The acclimatisation process begins with every new environment that the product travels into, but given that the boxes are sealed, the speed of acclimation is significantly slowed.

Therefore, if you have bought a product that has sat at a warehouse for a long time which just happens to have brought the product’s EMC to the point that it matches your Happy Place, then you would lay the floor and never have a problem, and never know the size of the bullet you had dodged.

But what if we weren’t that lucky? What if we use the example of Sydney as above but lay the floor while it is at 9% EMC, which is 4% different from our Happy Place.

In this case, based on our 6m wide raft:

|

Engineered Block Core Timber |

Will grow 19.2mm before it reaches its Happy Place |

|---|---|

|

Engineered HDF Core Timber |

Will grow 9.6mm before it reaches its Happy Place |

|

Engineered Hardwood Ply Core Timber |

Will grow 28.8mm before it reaches its Happy Place |

|

Solid Bamboo Flooring |

Will grow 48mm before it reaches its Happy Place |

Again, these numbers are halved because this is a movement that happens from the centre of mass of the floor, and half happens in each direction.

Therefore, we will have:

|

9.6mm on each side of the raft with Engineered Block Core Timber |

|

4.8mm on each side of the raft with Engineered HDF Core Timber |

|

14.4mm on each side of the raft with Engineered Hardwood Ply Core Timber |

|

24mm on each side of the raft with Solid Bamboo Flooring |

All of which we have not accounted for. Mic Drop!

HDF Core vs. Block Core Timber Difference

The increase is almost insignificant for Engineered HDF Core Timber. We can pretty much throw what we want at it, and it behaves how we need it to.

With Engineered Block Core Timber, things become decidedly sketchier. This will be one of those cases where sometimes you win, sometimes you lose, but if there is a season of extended rain and humidity, the floor will be like a coiled spring just waiting to be released.

Engineered Hardwood Ply Core Timber will be sketchier, and Solid Bamboo Flooring will likely be a problem immediately.

So How Do We Prevent This?

The simple answer is to Acclimatise the floor. And how do we do this? We simply bring the product into our home and do nothing. Almost nothing.

The best thing to do is to stack the boxes of flooring in the rooms where they are likely to be laid and simply cut open the ends of the boxes. If there is an internal plastic membrane in these boxes, then open this as well. Do not take the product out of the boxes. Opening the ends of the boxes is sufficient to let the product breathe and start making its way to its Happy Place.

You may ask why you don’t take the product out of its boxes, and the answer is simple. Engineered timber is made of different layers of different species of timbers that are laminated together. If they are unrestrained while going through their initial growth cycle, these different timbers will acclimate at different rates, which will likely cause your boards to bend and bow. This will make them far harder to install and will make the floor far noisier.

Restraining the boards while they are acclimating is akin to the difference between putting water straight into your freezer or first putting it into an ice cube tray. They will both turn to ice. One is just a lot easier to work with.

How Long Do I Let My Floor Acclimatise?

This is the ultimate question. Ultimately, you want to lay your floor when it is in its Happy Place. This is very difficult to achieve, though.

To do this, you must monitor your flooring daily and constantly check it with a moisture meter. You will want to take as large a sample group as possible and average the EMC of these boards. Therefore, if you choose to test 20 or 100 boards, you will take the average EMC and lay the floor when this average is at the floor’s Happy Place.

This can be a little tricky, though having an installer ready to go when your floor reaches its Happy Place is not feasible. It is also unlikely that you have a moisture meter that can read the core EMC of your timber flooring.

The other way is just to give the floor a healthy Acclimation period. Generally, the longer, the better. Between 2 and 4 weeks is a fairly healthy period, this will not be as accurate, but the fluctuations between the highs and lows of the year are rarely as big as the initial growth cycle of an engineered timber floor. Also, remember that the fluctuations occur above and beyond the initial growth Cycle, so it is the Initial Growth Cycle that we are trying to get out of the way.

Breaking the Rules

Once you know the rules, you can break them.

Famous last words.

When a supplier puts rules into their installation document, it is always our advice that you follow these instructions. These instructions are written to cover all unforeseen eventualities and have a built-in margin for error. But now that we know what this margin for error is, we can break the rules, can’t we?

No.

Please understand that if you install a floor that falls outside the supplier’s installation instructions and there is a problem of any kind with that floor, the supplier will thank you for choosing their product and wish you well in life. And that is it.

Having said that, we understand that many people will choose to break these rules anyway. I am not speaking from a position of loftiness here, as I have done it myself in my own home three times. However, if you break the rules, please don’t do it off the back of this blog.

Why Are Rules Important?

This is a great question, and it is about giving your floor the best chance in life that it can have.

As I have mentioned, suppliers have margins for error written into their installation guides. This should cover you in most cases. However, there are cases where even the greatest safety margins are insufficient.

For example, in May 2023, Mullumbimby had an average EMC of 82%, historically between 69-77%. In the best case, this is a 5% increase in EMC, and we have already looked at how this affects the product.

This was undoubtedly due to the floods that occurred in the region, and in fairness, it is an eventuality that timber flooring suppliers cannot prepare for. As a result, suppliers have had a year of dealing with complaints about timber flooring, and many have issued statements to retailers explaining that this is an act of God and that they are not responsible.

If these floors had been properly acclimated before installation, there is every chance they would have fared much more successfully than floors already sitting at the end of what the supplier has asked for in their installation guide.

It simply means stacking every odd you can in your favour before the die is cast.

Frequently Asked Questions

The proper method is surprisingly simple: stack the boxed flooring in the rooms where it will be installed, cut open the ends of the boxes, and if there's an internal plastic membrane, tear that open too. Please don't remove the boards from the boxes altogether; this restrains them during initial expansion to prevent warping.

This allows the timber to adjust gradually to your home's temperature and humidity. Generally, leave them for 2-4 weeks before installation for best results.

Engineered HDF Core Timber shows the least movement with humidity changes, approximately 2mm per meter for every 5% EMC change. This makes it the most stable option and forgiving if not adequately acclimatised. For comparison, Solid Bamboo moves 10mm per meter (5 times more), Engineered Hardwood plywood core moves 6mm, and Engineered Block Core moves 4mm. If stability is your priority, especially in areas with significant humidity fluctuations, Engineered HDF Core is your best choice.

That's dangerously incorrect. While engineered timber is more stable than solid timber (expanding 3-4 times less), it still requires proper acclimatisation. Timber manufactured overseas is typically dried to 7-10% EMC, while Australian environments often require 13-14% EMC for stability.

Without acclimatisation, you risk significant expansion after installation that exceeds the standard 12mm expansion gap - potentially causing buckling or other damage. Any installer who says acclimatisation isn't necessary is likely taking shortcuts that could void your warranty.