Last updated 10/2/25

Is there more to hybrid flooring thickness than you think? We know it to be true. When customers ask this question, what is the best hybrid flooring thickness? the answer can take some time to explain adequately.

Sometimes, there are distinct and undeniable reasons why thicker hybrid flooring might be better. However, manufacturers create different hybrid flooring options with distinct differences within this flooring category.

So, if you are not a flooring expert, it can leave you confused and sometimes even misled once you realise the truth.

This article examines everything you need to know about hybrid flooring thickness.

Overview:

- Thickness, What Thickness?

- Why Thicker is Better is So Many Cases

- Core and Ware Layer Ratio

- Things to Remeber

Thickness, What Thickness?

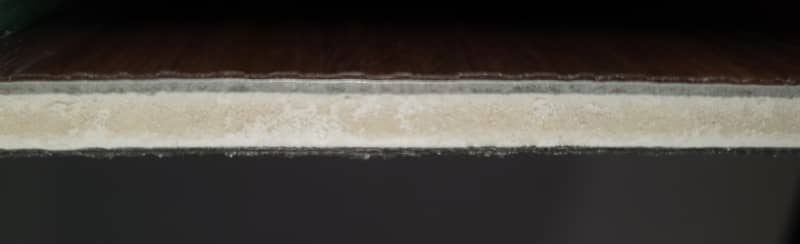

We are not talking about what you see from the top (length and width) but what you don’t see when the hybrid plank is on the floor. We refer to the thickness of the hybrid product, which incorporates various layers and directly influences its weight per cubic meter.

In Hybrid, Typically Thicker is Better

Weight strength and stability generally increase with thickness. For example, a 7mm thick board weighs more per square meter than a 6mm wide board, provided they have the same thickness of wear layer and underlay.

The main reason thicker is better for hybrid flooring in most cases is that when it’s thicker, it generally has a thicker core, which lends the product more weight, which helps with the following:

- The floated floor will sit better with more weight and will be less likely to bounce underfoot and move from its original place.

- The thickness & weight of the hybrid core against the thickness and weight of the wear layer is more stable.

Expert Insights From Dean Billett

28+ Years of flooring industry experience

Thicker can be better in unforeseen circumstances, such as when you want to meet the same height between the flooring and ceramic tiles that have already been laid.

Early Problems With Hybrid Flooring

This information is still inconclusive, and not all professionals agree. That being said, here is our firm, professionally backed opinion, confirmed by other industry experts:

- When hybrid flooring first arrived in Australia in the SPC format (WPC had been largely ignored up to this point), an issue quickly became apparent across all suppliers: In isolated areas of the home, the product would balloon off the floor when the sun heated it up and then settle down almost as soon as the sun left this area.

- As this was a new product category, and there was no case history, it was up to those on the ground to look into this and determine what was happening. There was no diagnosis for this problem, and many suppliers tried to approach the rectification from the viewpoint of product categories they were already familiar with.

- The first thing suppliers tried was to increase the size of expansion gaps. However, this would not have made any difference from the investigations of other reps and me on the road simultaneously. At Signature floors (my old work), we had specified a ‘Raft Break’ (Expansion Break under a different name) of 5mm. In the cases I investigated, even when the flooring had sat up off the floor by 40mm or more, there was still a break of 5mm around the perimeter.

Growth Issues Resulted

This meant that the raft was not growing in the same way a laminate or timber floor would because:

- The growth was isolated to a specific point of the floor without engaging the perimeter break, and,

- The growth would happen within 20 minutes, and then it would take about 20 minutes to go down after the sun left the area on the floor.

Hybrid takes its name because it uses certain elements common to Vinyl Plank Flooring but installs like a laminate floor. The elements of the floor it has in common with Vinyl Plank Flooring are its picture Film and the wear layer.

One of the issues with vinyl plank flooring is its temperature sensitivity. This means that the vinyl wear layer of a hybrid floor is also temperature-sensitive. This wear layer is so strong that it often carries a 25-year wear warranty!

When two products are laminated together, and one is subject to stress caused by environmental conditions, the stress can cause a change in the stable layer. I deduced that this was what was happening to hybrid flooring.

Expert Insights From Levi Saunders

Online Retail Specialist & Flooring Content Creator

An expansion break is a gap that must be left around the perimeter of a flooring raft when installing the floor. They are sometimes called for in the middle of a floor to allow the flooring products to expand and contract as required due to environmental change. Be sure to follow supplier guidelines about expansion gaps.

More Evidence Needed

I needed to show some evidence to my ‘Conspiracy Theory’ so I didn’t get ‘Fact Checked’. At the time, Signature floors had three different Hybrid ‘Recipes, ’ if you will, all from the same supplier using the same core composition. This meant that I was comparing apples with apples.

The Three Hybrids we had at the time had the following characteristics:

- 4mm with a 0.3mm wear layer and 1mm underlay

- 5.5mm with a 0.5mm wear layer and 1.5mm underlay

- 7mm with a 0.5mm wear layer and 1.5mm underlay

It was the 5.5mm product that was causing the problems. Others in the company did not believe me, so I needed to make my case.

I looked at the core thickness of each of the products and then compared that to the wear layer. The Core thicknesses were 2.7mm, 3.5mm, and 5mm for the products respectively. When I ran the numbers and looked at the ratios, the cores of the 4mm product and the 7mm product were around 150% heavier about the wear layer than the 5.5mm product. This said to me that the .5mm wear layer had the strength to move the core of the 5.5mm product, but for the other 2 products, the core was too heavy for it to move.

What Does This Mean?

After following the scientific method, I concluded that the heavier the core about the wear layer, the more stable the product.

If the core is too thin for the relative wear layer, the product is open to this type of phenomenon and the associated damage that this causes to the product. Thickening the 5.5mm to 6mm core put enough weight against the wear layer to stabilise the product. 0.5mm may not seem like a lot, but increasing the core thickness from 3.5mm to 4mm saw an increase of almost 15% in the weight of the core and solved the problem.

So, Where Did This Idea Come From?

- Vinyl Planks (predominantly PVC) have had issues with temperature expansion and shrinking. The wear layer on a hybrid plank is also made of PVC (polyvinyl chloride).

- So, the hybrid wear layer was heating up and expanding, still bonded to the core, which caused the floor to lift. The 5.5 mm product wear layer had enough strength to raise the boards off the floor. The product would return to normal as the sun dropped and the temperature dropped. But the first time this occurs, the flooring joints are irreversibly damaged.

What Can We Learn?

In this case, the thickness of the hybrid is better when the ratio between the wear layer and the core is maintained. You will notice now that most hybrids are 6mm and above. And this was due to some of the investigating we did.

But our work doesn’t end there.

Thickness and Joins

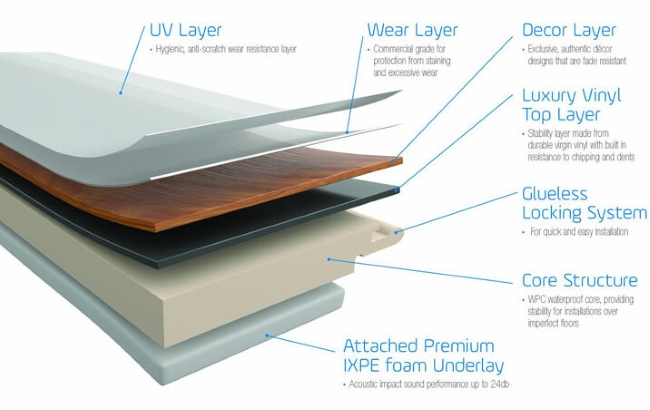

A thicker core gives you more area to machine a solid join into the product. For example, if your product is only 5mm thick with a 1.5mm underlay and 0.5mm wear layer, you are only left with 3mm to machine a join into to hold the floor together. The subfloor will need to be perfect because any movement will cause this joint to break over time. It is not a matter of ‘if’ it will break, but rather ‘when’ it will break.

Expert Insights From Clem Sturgess

20+ years' experience in hard flooring

Although hybrid is very heavy and hard, this can make it quite brittle, so the subfloor has to be within the supplier's requirements.

In the case of Terra Maters 9.7mm product, where you have a 2mm backing and a 0.7mm wear layer; you are left with 7mm to machine a join into, to create a strong and durable product.

Is a Thicker Hybrid Product Always Better?

There is a caveat:

Hybrid is an overarching category. Within this banner, there are two main kinds:

- Air-rated core (WPC, IPC, Solid PVC and others)

- Solid core (SPC)

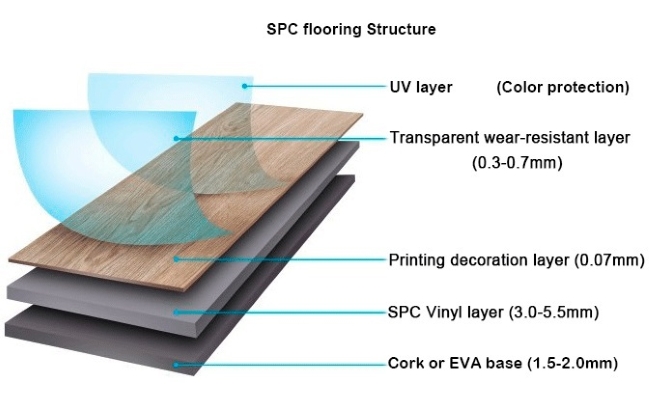

An SPC hybrid contains the following layers:

- Polyurethane wear layer

- Picture film or Decor

- A core that comprises at least 80% limestone

- Underlay

A WPC Hybrid contains the following layers:

- Polyurethane wear layer

- Picture film or Decor

- A thin sheet of vinyl to protect the porous core

- A core that varies between wood or stone polymer composites with the addition of PVC and a foaming agent

- Underlay

Expert Insights From Clem Sturgess

20+ years' experience in hard flooring

Customer experience & disappointment can occur when a customer is not told the difference between solid core and aerated core hybrid flooring before purchase and later discovers this. Many companies would prefer to sell aerated core, leave this explanation out, and may refer to the product as simply PVC core. This is an opportunity to give people all the information they need to make the best decision for their flooring project.

Thicker is Only Sometimes Better

A competitor of ours advertises both 5.5mm & 8mm hybrid products:

- On the surface, the 8mm hybrid could be the best option until you realise it’s a WPC air-rated core product. This product has no choice but to be thick. For example, a 5mm product with an air-rated core would not have the strength needed with insufficient weight to hold it in place or insufficient core thickness to machine a joint with any kind of strength into the product.

- They don’t mention that the product is an “8mm WPC hybrid” and label it as a “hybrid”. That’s a pretty important detail to miss.

- Also, remember that an aerated core product has far less weight than a solid core product. This means that the weight-to-wear layer ratio is out of kilter with this type of Hybrid Flooring.

So there are three things to watch:

- The thickness

- Solid-core (SPC) or Aerated-Core (WPC)

- Is the retailer providing all the information?

The air-rated core must be approximately 44% thicker than solid core products to have comparable strength.

Expert Insights From Dean Billett

28+ Years of flooring industry experience

We believe Solid Core Hybrid wins every battle with air-rated Core Hybrid, except for acoustics.

Expert Insights From Raquel Billett

Interior Décor Expert

Regarding SPC hybrid and freight, we haven't had any issues or complaints from customers. In comparison, timber on a pallet is generally lighter but longer than a hybrid, making freight costs between the two flooring types comparable. This means customers have a general expectation of freight cost subject to the market, and Hybrid generally fits within most people's expectations.

Sometimes, retailers will try to sell WPC hybrids (air-rated core) over SPC (solid core) because they are lighter and easier to move around, so freight costs are lower. However, this is not a strong enough reason to give Aerated Core preference, and we strongly favour Solid Core Hybrid from a reputable supplier such as Imagine Floors in almost all cases.

In collision: When it comes to hybrids, thicker is better, depending on what you compare it to. SPC at 5.5mm is likely as strong as an 8mm hybrid in a WPC.

FAQs

Not necessarily. While thickness can be important, the ratio between the wear layer and the core matters more. For solid core (SPC) hybrid flooring, 6mm and above typically provides good stability. However, an 8mm air-rated core (WPC) hybrid might not be as strong as a 5.5mm solid core hybrid. It's more important to consider the type of core (SPC vs WPC flooring) rather than just the thickness number.

SPC (Solid Core) hybrid contains at least 80% limestone in its core, making it denser and more stable. WPC (Wood Polymer Composite) has an aerated core with wood or stone polymer composites mixed with PVC and a foaming agent.

While WPC needs to be thicker to achieve comparable strength, SPC generally wins in most applications except for acoustics. An air-rated core needs to be approximately 44% thicker than solid core to have similar strength.

Early 5.5mm hybrid floors sometimes experienced issues where the floor would "balloon" in sunny areas due to an imbalanced ratio between the wear layer and core thickness.

Industry investigation found that increasing the core thickness provided better stability against the wear layer's expansion and contraction. This is why most hybrid flooring now comes in 6mm and above, ensuring better stability and durability.